TURBO CARVER uses an air turbine that rotates at 400,000 RPM. A typical rotary tool at a hardware store rotates at 35,000 RPM. The turbine rotates on 2 high precision, state of the art, ceramic ball bearings that are especially designed and lubricated needing no oiling.

Air Compressor Requirements:

The Turbo Carver consumes 2 cubic feet per minute (CFM) of air pressure. The most important rating for a compressor is the Cubic Feet Per Minute (SCFM) or (CFM) and not the total air pressure (PSI).

Usually an airbrush compressor is .5 HP and does not provide 2 CFM as spraying paint requires less volume as is necessary for an air tool.

The compressor should be a piston type air compressor with a rating of at least 3/4 HP and 2 CFM.

Turbo Carver air compressors require no oiling, come with a foot control, and are much quieter at about 60 dbl. (About the volume of a typical hand held hair dryer on low). They are designed to be easy to use and come all set up to power your Turbo Carver.

Burs:

Turbo Carver only uses 1/16 inch diameter cutting bits, called Friction Grip Dental burs. These burs are available in Carbide, Diamond, Stone and Rubber. We stock about 30 of the most appropriate burs used for engraving and carving.

TECHNICAL SPECIFICATIONS:

- Air Usage: Consumes 2 CFM

- Air exhaust: Silicone composite valve device for dust protection

- Bearings: 2, shielded, no lube, angular contact, miniature precision high-speed bearings

- Bur Chuck: Friction type, thumb ejection to conveniently change burs,

- Concentricity deviation: 0, 02 mm

- Dimensions: 4 inches total length, 1/2 diameter

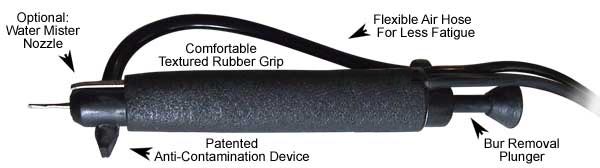

- Handgrip: Textured rubber handle for comfort and control

- Head Size: 9.40 cm - 3/8 inch for ease of visibility and accessibility

- Torque: 690 gcm - 3.0 Ncm

- Turbine: Nylon composite for superior concentricity and fast & accurate detailing and increased durability

- Speed: Turbine rotates at speeds ranging from 380,000 rpm to 420,000 rpm, 6700 rps,- 180,000 rpm to 300,000 rpm under load

- Weight: 13.7 grams or 1/2 ounce

- Construction: Lightweight ABS composite which allows for strength, durability, and resistance to water corrosion damage over other handpieces constructed of plated brass or aluminum.

Water Mist Spray - This is the only handpiece available on the market with an optional Water Mister spray attachment. This atomized cloud of water eliminates 95% of the fine dust and fumes associated with carving in materials like bone, egg, glass, gemstones, eggshell, antler. It also keeps the bur cool for longer life and prevents any kind of fracturing of the material being carved. Creating a finer cut and strengthening porous materials, is another advantage of this technology.

TECHNICAL AND PRODUCT SPECIFICATIONS

Download Instructional Manual

IN APPLICATIONS LIKE THIS

MODERN PRECISION INJECTION PLASTIC IS

REPLACING METAL THE SAME WAY

INTEGRATED CIRCUITS REPLACED TRANSISTORS

All handpieces on the market today, with the exception of the Turbo Carver , are made using 40 year old technology. Turbo Carver uses cutting edge technology and is a radical innovation in handpiece design.

Our instrument weighs only 1/2 ounce. It can be used by people with arthritis and other joint maladies because there's no weight, vibration or torque transmitted to the handle. If you accidentally drop a metal handpiece, there is a good chance you will destroy the bearings or break the bur. Turbo Carver is so light, it resists breakage if dropped on the floor.

Because Turbo Carver is made from precision injection molded plastic it could be designed small and simple. It has been said and demonstrated that simplicity is elegance. The small, pen-like, size also increases your visibility and improves access in hard to reach areas.

IT IS THE ONLY INSTRUMENT

WITH A COMFORTABLE

TEXTURED RUBBER GRIP

Plastics are not affected by moisture, which is a serious problem for metal instruments. handpieces with aluminum handles are very susceptible to oxidation from moisture coming through the air lines. Oxidation is what sand paper is made from and it will destroy the bearings if it forms within the handpiece. For this reason, metal handpieces, require an expensive moisture trap installed in the air line. Unfortunately, the moisture trap will not prevent water vapor from getting into the handpiece while working with water as needed for hard materials.

Turbo Carver uses a one piece, carbon composite turbine assembly. There is no costly chuck to wear out and no wrench is necessary. Since there are fewer parts concentricity is superior to its metal counterparts thus reducing vibration and noise. Concentricity of the new turbine is between 0 and .0002".

NOTE: Don't let its small size and low weight fool you,

this instrument is as good or better in performance than the larger,

heavier and much more expensive metal counterparts.

Dirty drive air is the cause of many bearing failures. Turbo Carver comes with a 5 micron air filter, in-line with the foot control, which removes any oxides or minute particulates, that get through the main regulator water trap/filter.

Turbo Carver incorporates a miniature in-line air pressure gauge. This gauge is used to determine with more accuracy, the optimum setting on your air compressor regulator. Too little pressure and you won't get good results, too much and you risk destroying the handpiece. You can't rely on the gauge on the compressor because vibration and age reduce their accuracy. Also, pressure is lost in the tubing that goes between the regulator and handpiece. As much as 1 PSI can be lost per linear foot of tubing as well as filters.

All other air-driven handpieces have an inherent problem. They draw contamination into the front bearing whenever you operate the instrument. The effect is called Carman Street Vortex and is a leading cause for bearing failure. This means when the drive air to the turbine is shut off, it takes several seconds for the turbine to spin down. During this time the turbine becomes a vacuum pump and pulls airborne contamination into the bearings. Turbo Carver has solved this problem with a patented pinched valve/air regulator mounted on the exhaust port. This regulator maintains positive pressure within the turbine housing during shut down, thus preventing a vacuum from forming. Once the handpiece is turned off and set down, the one-way valve closes shut thus preventing dirt from entering through the exhaust port.

The second cause for bearing failure is heat buildup in the rear bearing. During operation air passes through the front bearing because of the path available around the spindle. However, there is not enough pressure within the turbine housing to get a good air flow around the rear bearing. The pinched valve on Turbo Carver increases the operational pressure within the turbine housing. This increased pressure makes it possible to create an air flow around the rear bearing.

The third reason for bearing failure is caused by the lubrication process. Manual and automatic lubrication is an imprecise procedure and too much oil is as bad as too little. Also, no matter how careful one is it is inevitable that dirt is going to be introduced during lubrication. Turbo Carver uses the most advanced bearing technology available to eliminate the need for external lubrication. The bearings used in this instrument are Lubricated For Life and because of this the bearings will last much longer. We have recently increased the warranty on the bearings from 3-to-6 months and additional testing will probably increase the warranty to 1-year in the near future.

Turbo Carver operates at 400,000 RPM making it the fastest in the world. The faster this type of instrument turns, the better it works.

Turbo Carver comes with a variable foot control at no extra charge, which is an expensive option with the competition. |